Actuators are an important part of a robotic set. Back in a day, NXT motors were a great choice to build a nice robot. Unfortunately, they are no longer available as well as the newer EV3 motors. We do not like the new Spike motors as the electrical interface is different and they are very expensive. There are motors similar to EV3 available at Chinese shops (ebay, aliexpress) but the quality of the construction is not very good (check out the post on main page, they have poor gearing). So, we decided to try to produce something based on available DC geared motors equipped with incremental encoders – that is all you need to get a decent robotic engine.

There are many types available but we selected two which seemed promising.

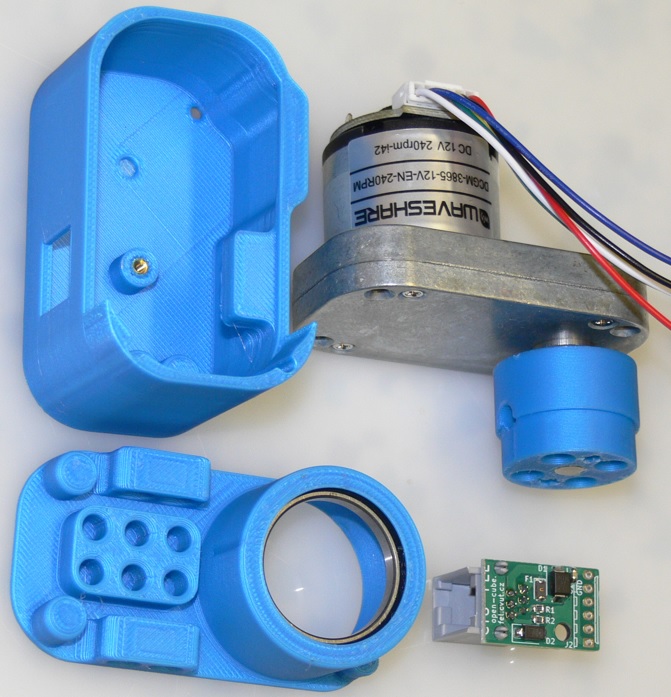

DCGM-3865-12V-EN-240RPM from Waveshare (L-shaped Permanent Magnet DC Gear Motor, Magnetic Hall Encoder, All-metal Gear Motor) and the GM25-370 9V 150rpm available elsewhere (e.g. https://www.laskakit.cz/motor-gm25-370-9v-150rpm-s-prevodovkou-a-enkoderem-/)

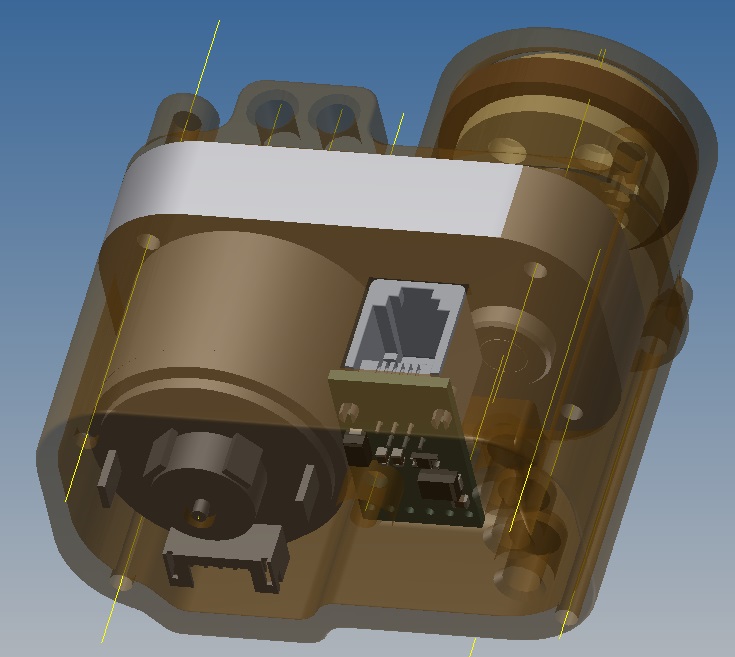

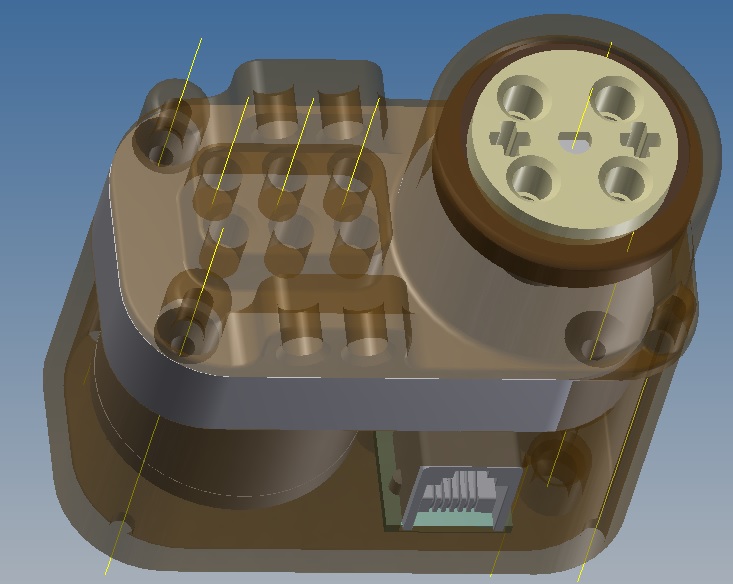

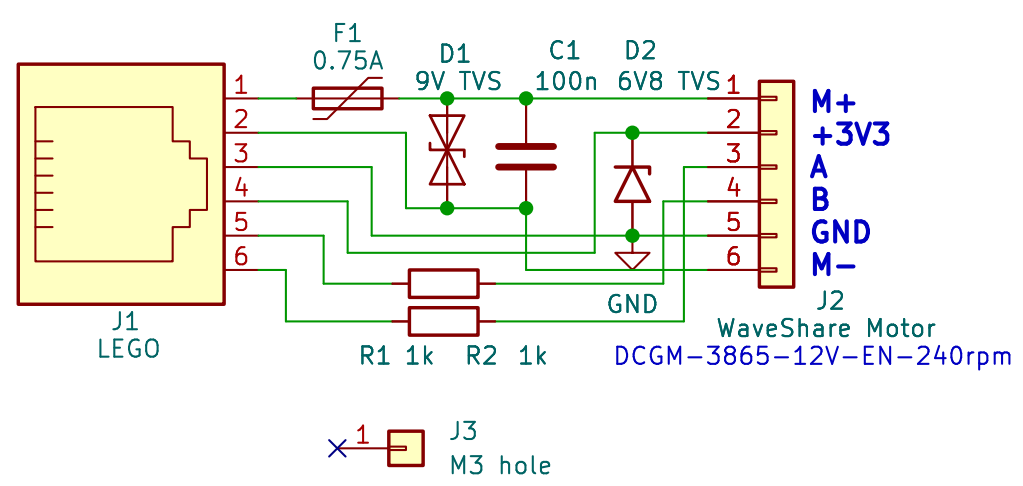

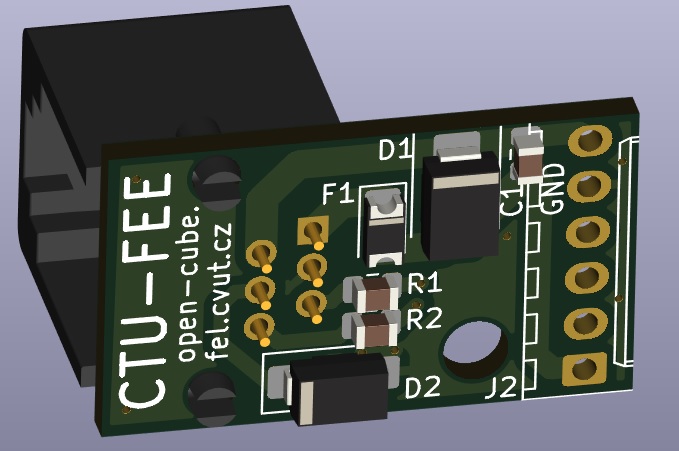

Till now we tested only the first one, see below and it worked just fine. We had to change two resistors on the motor PCB to make it compatible with Open-Cube motor port electronics (replace 10k pull-ups with 4k7). We tested the motors in the Segway like balancing robot and it worked just fine, see the video below. A bit of a drawback is high mass of the motor and the fact that it is not possible to use a shaft running through the motor.

The smaller motor awaits 3D design of the motor case. The PCB with a LEGO connector and some over-voltage and over-current protection parts will be used the same as for the larger motor.